How to make reeds on wood turning blank And Sharpen a wood scraper?

Marking out the reeds

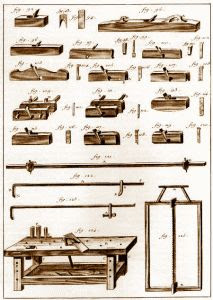

Outline reeds on a turning blank using your lathes indexing head as you would mark flutes. You can use a layout jig or the tool rest. With the lathe unplugged and the indexing pin in the head, position the rest parallel to the blank and raise it so the top of the rest is level with the middle of the blank. Draw a pencil along the tool rest to lay out the first reed. To mark each remaining reed, disengage the pin from the indexing head, rotate the head, and reinsert the pin in the appropriate hole.Carving the reeds

Use a well-sharpened carvers parting tool to outline the reeds. Secure the leg on the lathe with the indexing pin so that one of your layout lines is facing upwards, then cut a shallow groove along the line with the parting tool. Repeat for the other marked lines, then round the reeds between them by making cuts on each side of the grooves, rolling a flat carvers chisel slightly from side to side. Follow the legs contours, making the reeds wider at the top than at the bottom. End the tops of the reeds as you did the flutes, using a carving gouge of the proper size;the bottoms of reeds are often left open.How to sharpen a wood scraper

1.Filing the edges square

To file off the existing hook on a scraper, clamp the tool in a vise with one long edge facing up. Holding a sharp mill bastard file firmly with both hands as shown, make several passes back and forth along the edge of the scraper, exerting moderate downward pressure until the bun disappears and the edges are flat. To remove filings, periodically tap the file on a firm surface or use a file card. Turn the scraper over and repeat the process for the other edge.

2.Honing the edge

Secure a combination sharpening stone fine side up to a work surface with cleats and lubricate it as you would when honing a plane blade Holding the scraper flat against the stone, rub the face on the stone with a circular motion. Apply moderate pressure and continue until any roughness produced by filing disappears. Turn the scraper over and repeat for the other face. To complete the honing, hold the scraper edge down and slide it back and forth diagonally across the stone until the edge is smooth with sharp corners. Repeat for the other edge.3.Burnishing the edges to start a hook

Place the scraoer f lat on a work surface with the edge to be sharpened extending off the table. Holding a burnisher at a slight angle to the scraper, make several passes back and forth along the edge, applying strong downward pressure to start turning over the edge into a hook. Burnish the other cutting edge the same way; turn the scraper over and burnish the edges on the other face.

4.Completing the hook

Secure the scraper edge up in a vise Hold the burnisher almost perpendicular to the edge and run it along the edge in one direction until the edge swells slightly, turning outward on one side. For best results, apply moderate pressure. Then hold the burnisher so that the handle is at a 10to 15angle above the edge of the scraper and continue burnishing until the edge turns over. Repeat the process to form a hook on the other side of the edge, this time holding the handle with your other hand. The greater the pressure you apply,the bigger the hook. Turn the scraper over and burnish the opposite edge. Test the cutting edges on a piece of of scrap wood, burnishing them again, if necessary, until you have the hook you need for the job at hand.

REFERENCES:

MyBoatPlans® 518 Boat Plans - High Quality Boat Building Plans

https://plus.google.com/111656643197458342675/posts/D4Td27mZaZE

9,000 Wood Furniture Plans and Craft Plans For DIY Woodworking

https://plus.google.com/111656643197458342675/posts/NKs6z1jyPXK

The DIY Smart Saw Program:

https://plus.google.com/111656643197458342675/posts/WHMw93wGU3j

Ryan Shed Plans 12,000 Shed Plans and Designs For Easy Shed Building!

https://plus.google.com/111656643197458342675/posts/9ppNTAHcpRY

Komentar

Posting Komentar