How To Get a Perfect Finishing Woodworking?

Finishing wood involves process. You can get outstanding results by

taking the time to understand the processes involved in finishing, and

by taking your time to perform each process with care.

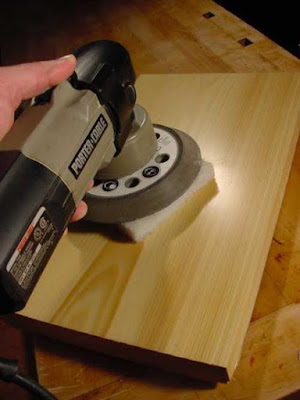

Great finishing depends on both mechanical and chemical processes. Mechanical processes are all about sanding and scraping wood, applying finishes with rags, brushes or spray equipment, and other techniques in finishing. Chemical processes have to do with the products you choose to use: Stains, dyes, oils, lacquers, varnishes, solvents, etc. Each finishing product has its own unique set of properties, which give you different effects or results, and the rules vary guiding the use of these different chemicals.

The wood finisher needs to know what is important and what is not so critical about all these processes. The aim in writing this is to give the finisher a straightforward and easy-to-read guide, but also one that is comprehensive enough to cover questions like, "Which sandpaper do I use?", and "How do I repair a boo-boo in the middle of my finishing job?" I hope that this guide will be a helpful reference in your quest for a perfect finish.

The finishing process is broken into six steps for the purpose of this guide:

Finish means end result. You need to think about the end result as you approach each step of the finishing process. How do you want the piece to look? Rustic, satin sheen, glossy, open-grained, mirror-smooth?

Obviously, the prep work for a rustic piece will vary from that of a fully-filled-grain, mirror-like finish. For the rustic look, you need not repair many physical defects in the surface; in fact, you may want to add some (finishers call this "distressing the surface"). If, on the other hand, you are aiming for a mirror-like finish you'll want every little defect to be repaired. Small defects look terrible in an otherwise smooth and shiny surface. So it is important that you begin with a clear idea of what you want to see in the end.

Your Goal in Surface Preparation

Preparing the surface, for most finishers, primarily

means sanding the wood. We scrape or sand the wood: (1) To get a smooth,

level surface for finishing, or (2) To get some "tooth" to the surface

to promote a mechanical bond with certain finishes, and (3) To get a

clean surface.

We are covering both approaches in these articles, and I suggest that anyone mastering finishes should practice both.

Often when you begin sanding a piece, it becomes obvious that there are low spots (dings, dents, scratches, gouges) that can be easily seen and repaired right away. You may also find splintering, chipping, veneer lifting or bubbling at this time also. Following are some procedures and products that you may find helpful in repairing these defects.

Steaming works best on dents where the wood fibers are not actually torn or broken. Depressions in the wood which have not torn or broken the wood fibers will become totally invisible after you've steamed and sanded them (Fig. 1). If the wood fibers have cracked around a dent, it may still steam out, but the small crack where the fibers were broken may appear as a dark line when finish is applied

These visible lines due to cracks through the cell structure (above) generally run cross-grain due to the nature of wood. They sometimes become less noticeable when the piece is stained. If they remain noticeable, the best time to deal with them is during step four, Adding Color to the Finish. Look under the section, Touching-up Defects.

There are numerous methods of steaming out dents in wood. In a furniture repair shop, the technician often has access to commercial steamers used in the upholstery shop, like the Jiffy model shown at the right, which costs $175 and up. These steamers do a fantastic job, but the expense is usually not justified unless you do alot of upholstery work along with your woodwork.

When using a steamer, simply pass the

steamer over the area several times, let it dry, and inspect to see if

the defect has "popped out." Sometimes this will take several

treatments. Once you are satisfied that it has gotten as good as it's

likely to get, let the area dry out and sand it flat with 120 grit

cabinet paper using a sanding block. You will soon find that steaming

out dents has a very high success rate!

REFERENCES:

MyBoatPlans® 518 Boat Plans - High Quality Boat Building Plans

https://plus.google.com/111656643197458342675/posts/D4Td27mZaZE

9,000 Wood Furniture Plans and Craft Plans For DIY Woodworking

https://plus.google.com/111656643197458342675/posts/NKs6z1jyPXK

The DIY Smart Saw Program:

https://plus.google.com/111656643197458342675/posts/WHMw93wGU3j

Ryan Shed Plans 12,000 Shed Plans and Designs For Easy Shed Building!

https://plus.google.com/111656643197458342675/posts/9ppNTAHcpRY

Great finishing depends on both mechanical and chemical processes. Mechanical processes are all about sanding and scraping wood, applying finishes with rags, brushes or spray equipment, and other techniques in finishing. Chemical processes have to do with the products you choose to use: Stains, dyes, oils, lacquers, varnishes, solvents, etc. Each finishing product has its own unique set of properties, which give you different effects or results, and the rules vary guiding the use of these different chemicals.

The wood finisher needs to know what is important and what is not so critical about all these processes. The aim in writing this is to give the finisher a straightforward and easy-to-read guide, but also one that is comprehensive enough to cover questions like, "Which sandpaper do I use?", and "How do I repair a boo-boo in the middle of my finishing job?" I hope that this guide will be a helpful reference in your quest for a perfect finish.

The finishing process is broken into six steps for the purpose of this guide:

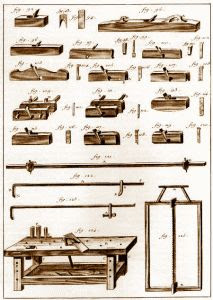

- First, we begin with Preparing Your Woodwork for Finishing. This step will cover sandpapers, scrapers, sanding machines, wood putties and body fillers, and tips on getting prep work done quickly.

- Second, we move to Adding Color to Raw Wood, our section on pre-coloring the wood with dyes and pigment stains, or with amber-toned products like finishing oils or shellacs. We also discuss the practice of "conditioning" certain woods to reduce blotchiness when adding stains.

- Third, we discuss Sealing the Raw Wood Surface. What does it mean to "seal" the wood? What products are used for this process?

- The fourth step, Adding Color to the Finish, is actually all about how to add color to a piece after it has been sealed. In this section we discuss glazes, toners and spot color repair methods.

- The fifth step deals with the actual application of final finish coats, and is simply called Topcoating. Various finishes are discussed, as well as tecniques for applying them.

- Sixth, we end with Finessing the Finish. This section is all about the things you can do to complete, or adjust the sheen of the finish you've applied.

Finish means end result. You need to think about the end result as you approach each step of the finishing process. How do you want the piece to look? Rustic, satin sheen, glossy, open-grained, mirror-smooth?

Obviously, the prep work for a rustic piece will vary from that of a fully-filled-grain, mirror-like finish. For the rustic look, you need not repair many physical defects in the surface; in fact, you may want to add some (finishers call this "distressing the surface"). If, on the other hand, you are aiming for a mirror-like finish you'll want every little defect to be repaired. Small defects look terrible in an otherwise smooth and shiny surface. So it is important that you begin with a clear idea of what you want to see in the end.

- Your Goal in Surface Preparation

- Repairing Defects in Raw Wood

- Scraping and Sanding Raw Wood

- Proof-reading Your Prep Work

- Dust Removal

Your Goal in Surface Preparation

Preparing the surface, for most finishers, primarily

means sanding the wood. We scrape or sand the wood: (1) To get a smooth,

level surface for finishing, or (2) To get some "tooth" to the surface

to promote a mechanical bond with certain finishes, and (3) To get a

clean surface.

For most finishes, it is important to have a smooth, level

surface. There may be times when a rustic look is your object, and a

rough surface with dents and dings may be desirable then, but if your

aim is a smooth, level finish, then you need to apply your finish to a

smooth, level surface.

At the same time, most of the film-forming finishes need

some "tooth" to the wood in order to help the initial coats adhere well.

For this reason, it is usually unwise to "over-sand" the wood ---

meaning to sand it up to too fine a grit. Sanding raw wood to a very,

very fine grit is usually a waste of time, a waste of sandpaper, and for

the extra labor and expense you get less adhesion at the raw wood to seal coat level.

Another important factor in promoting adhesion of your

seal coats is having the surface clean. Again, proper sanding goes a

long way in getting a clean surface for finishing.

To

re-cap, your goal in prep work is to get a smooth, level surface, while

providing some "tooth" for the seal coats, and a clean surface.

Repairing Defects in Raw Wood

There are two basic approaches that finishers make in taking care of defects during the finishing process. The first is to repair defects during the prep stage, making repairs directly to the raw wood. The second is to make repairs sometime after the wood has been sealed, when it becomes easier to fine-tune color matching.We are covering both approaches in these articles, and I suggest that anyone mastering finishes should practice both.

Often when you begin sanding a piece, it becomes obvious that there are low spots (dings, dents, scratches, gouges) that can be easily seen and repaired right away. You may also find splintering, chipping, veneer lifting or bubbling at this time also. Following are some procedures and products that you may find helpful in repairing these defects.

- Steaming out Dents

- Filling with Wood Putties

- Sculpting with Body Fillers

- Using Adhesives

Steaming works best on dents where the wood fibers are not actually torn or broken. Depressions in the wood which have not torn or broken the wood fibers will become totally invisible after you've steamed and sanded them (Fig. 1). If the wood fibers have cracked around a dent, it may still steam out, but the small crack where the fibers were broken may appear as a dark line when finish is applied

These visible lines due to cracks through the cell structure (above) generally run cross-grain due to the nature of wood. They sometimes become less noticeable when the piece is stained. If they remain noticeable, the best time to deal with them is during step four, Adding Color to the Finish. Look under the section, Touching-up Defects.

There are numerous methods of steaming out dents in wood. In a furniture repair shop, the technician often has access to commercial steamers used in the upholstery shop, like the Jiffy model shown at the right, which costs $175 and up. These steamers do a fantastic job, but the expense is usually not justified unless you do alot of upholstery work along with your woodwork.

A more economical purchase would be a "travel steamer"

like the one by Samsonite shown below, left. You can find these and

similar models in discount stores or department stores, often for about

$20. Personally, I like "free" the best,

so I use a clothing iron that my wife retired. Although it is a steam

iron, I do not use the steam function of the iron because it is

difficult to control. Instead, I use wet or damp rags placed over the

defects, and I apply the iron over the rag to produce steam. The iron is

set on a fairly hot "cotton" setting. A bonus is that I can use this

iron for applying edge-banding to my projects as well.

REFERENCES:

MyBoatPlans® 518 Boat Plans - High Quality Boat Building Plans

https://plus.google.com/111656643197458342675/posts/D4Td27mZaZE

9,000 Wood Furniture Plans and Craft Plans For DIY Woodworking

https://plus.google.com/111656643197458342675/posts/NKs6z1jyPXK

The DIY Smart Saw Program:

https://plus.google.com/111656643197458342675/posts/WHMw93wGU3j

Ryan Shed Plans 12,000 Shed Plans and Designs For Easy Shed Building!

https://plus.google.com/111656643197458342675/posts/9ppNTAHcpRY

Komentar

Posting Komentar